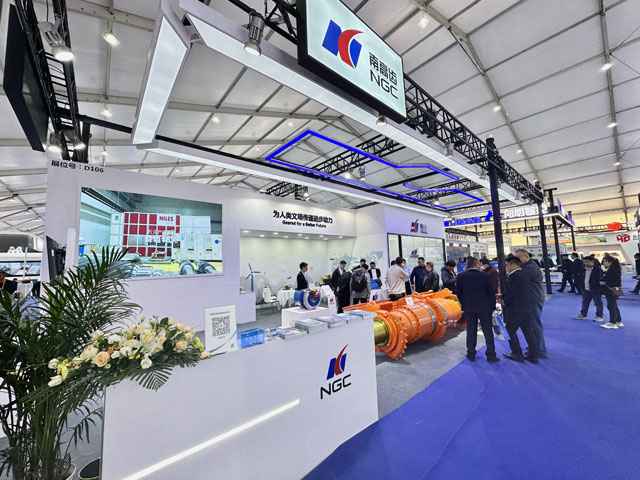

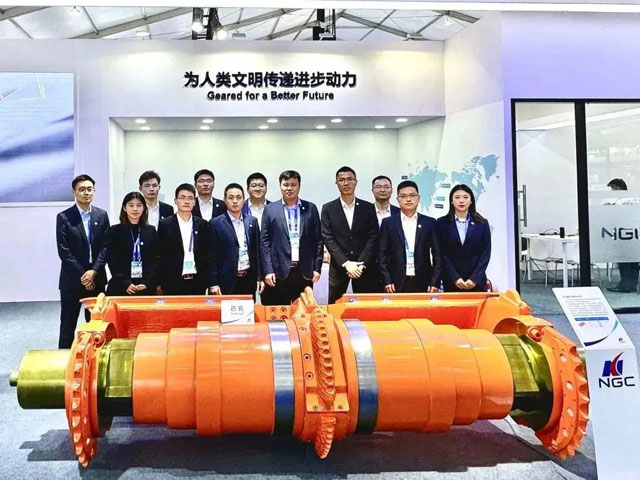

Located in China’s “Golden Triangle” energy hinterland, Ordos is a important center for large-scale coal production. On May 6-8, 2023, it ushered in the 17th Ordos International Coal and Energy Industry Expo. The event was held simultaneously at the Ordos International Convention and Exhibition Center of Kangbashi District and at the All People Fitness Center in Dongsheng District. More than 1,000 enterprises attended the event with an aim to strengthen energy cooperation and pursue common development, and featured an exhibition area of over 100,000 ㎡.

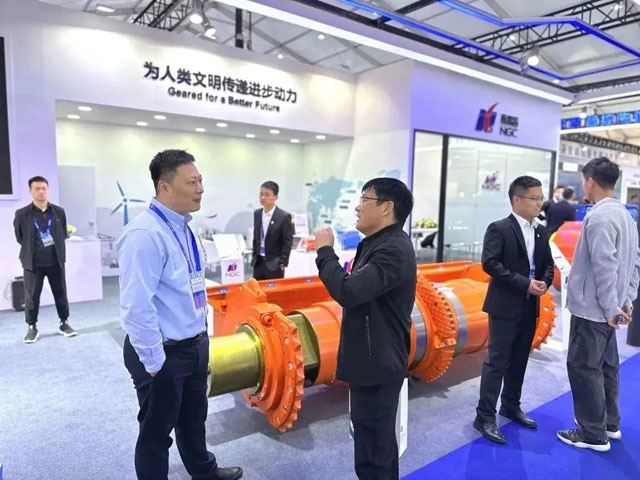

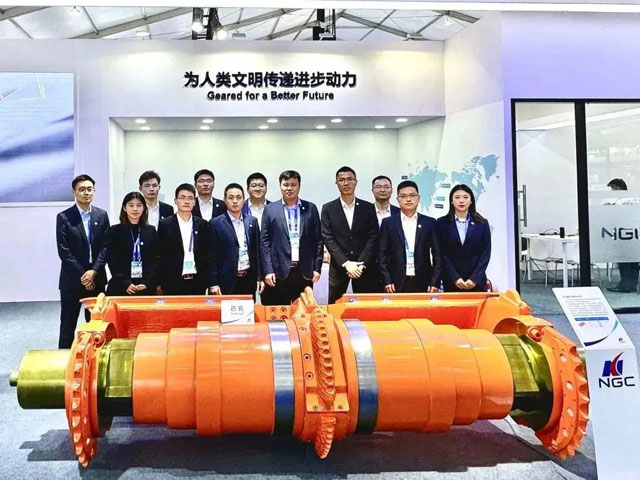

As an enterprise working hard in the field of drive equipment for over 50 years, NGC was present at the primary venue of the event, the Ordos International Convention and Exhibition Center. Here it displayed such products as anchor diggers, scraper and belt conveyors, and the GearSight smart platform.

These products have already become preferred options for ancillary equipment with numerous large-scale coal industry groups thanks to their special features of lower noise, smaller footprint, lighter weight and higher stability. The GearSight smart platform can ensure the predictive maintenance of products, thus providing users with more efficient and stable diagnostics and equipment monitoring.

NGC provides quality products and R&D services, which were widely praised by the professional visitors at the exhibition.

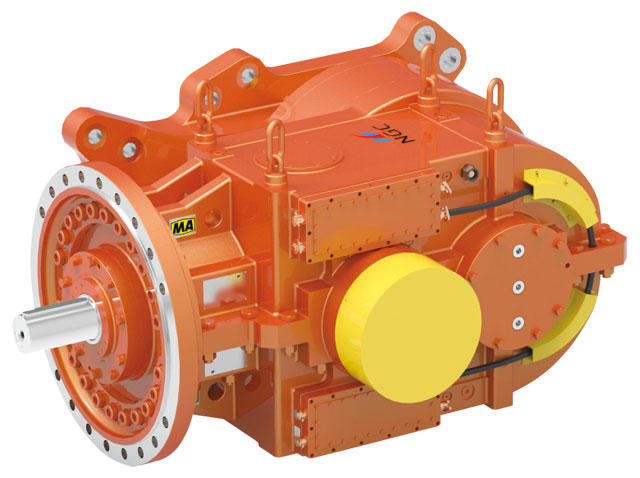

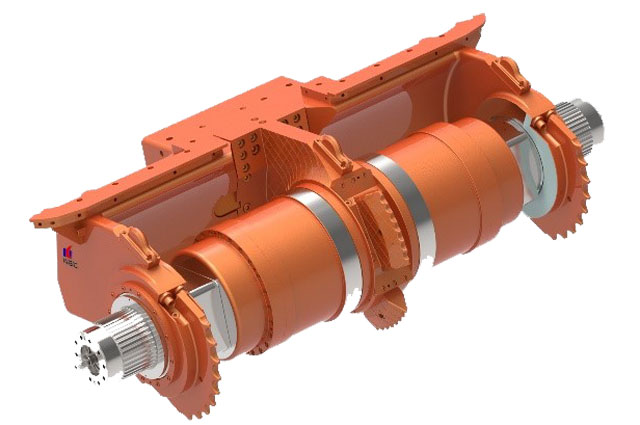

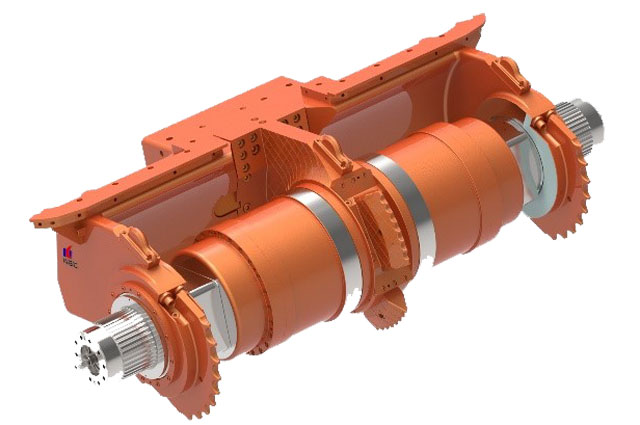

After its casing design upgrade, the gearbox for high-power scrapers has the added advantages of higher efficiency, a longer service life and higher reliability, as well as higher impact resistance. This makes it more suitable for operation under harsh working conditions and provides a strong guarantee for the safe operation of the scraper conveyor and the stable production of coal mines.

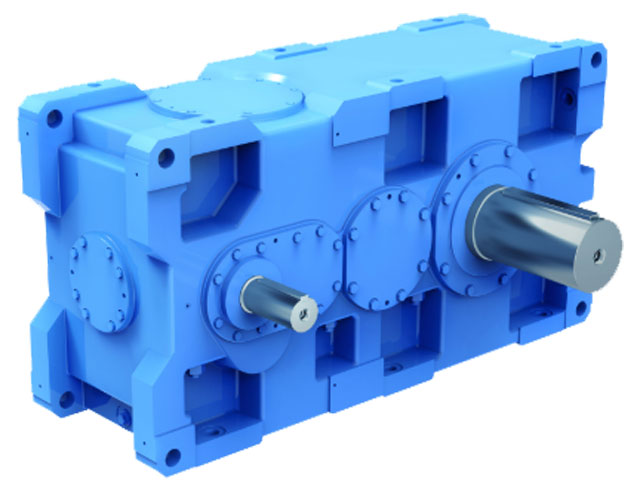

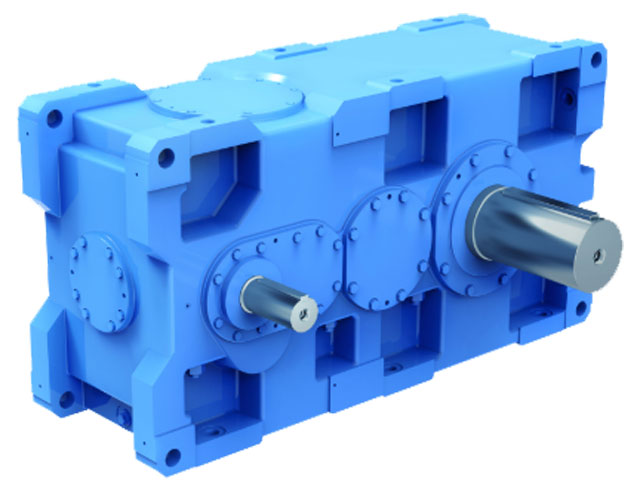

The gearbox of the belt conveyor features a modular design concept and a higher power density. Thanks to unique technologies such as gear modification, thermal power analysis and optimization, its bearing capacity is higher, its cooling more efficient, its casing stronger and its quality more reliable. As a result, it has been widely used in major coal groups such as National Energy Group Shendong Coal, Shandong Energy Group, Shaanxi Coal and Chemical Industry Group, China Coal Energy and Pingdingshan Coal Industry Group.

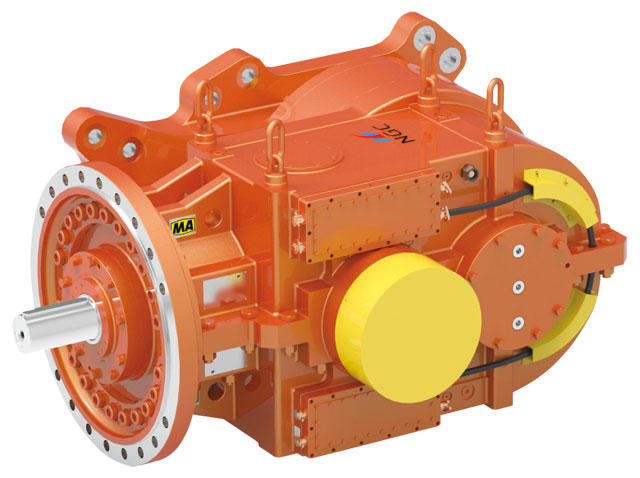

The cutting gearbox for anchor diggers features multiple advanced technologies such as gear engagement analysis technology, planetary transmission uniform load analysis, structural topology optimization, bearing calculation analysis and thermal power analysis. The product has been highly praised by users for its improved air-tightness, higher transmission efficiency and higher reliability compared with similar products. The 540kW cutting gearbox has been developed jointly by NGC with the China Railway Construction Corporation and Shendong Coal Industry Group. The overall performances of this gearbox are on a par with the world’s most advanced products.

Meanwhile, based on NGC’s rigorous system for data collection and operating analysis, the GearSight smart diagnostics platform can diagnose and monitor the working conditions of equipment more efficiently and reliably. This enables predictive product maintenance, improved efficiency for plant equipment and lower operating costs.

Keeping watch on new development trends within the coal industry

Under the new requirements for intelligent construction, along with safe and efficient production in coal mines, coal machinery equipment is currently advancing in the direction of intelligence, environmental-friendliness and digitization. NGC has always pursued an in-depth expansion within the coal machinery gearbox industry, seizing new development trends and providing the coal and coal chemical industries with outstanding and efficient industry-wide equipment transmission solutions. The company also provides gear drives for a variety of industrial equipment, including open-pit mining equipment, coal mining, transmission and dressing equipment, coal mills, air separation and furnaces, as well as smart monitoring of online conditions and intelligent maintenance services.

NGC has always insisted on safe, efficient, green and intelligent scientific innovation, promoting environmentally-friendly and sustainable work for the country’s Dual Carbon Goals. In this way, the company provides its clients with a variety of stable and efficient domestic and customized supporting solutions, helping them improve production efficiency in terminal enterprises. We have thus assisted our customers in optimizing their production processes and contributed our know-how to accelerating the digital transformation of the manufacturing industry.

In the future, we will continue to be actively involved in the upgrading of China’s coal industry, and further committed to entering a fast track of high-end, intelligent and green manufacturing for the world.

.png) NGC Joins Hands with Mobil™ to Empower the Wind Energy Market

Recently News

NGC Joins Hands with Mobil™ to Empower the Wind Energy Market

Recently News NGC’s “Code Scanning Service”

NGC’s “Code Scanning Service”